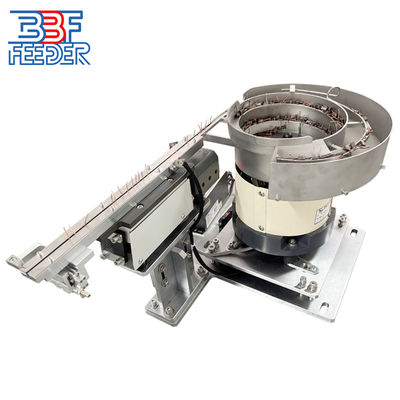

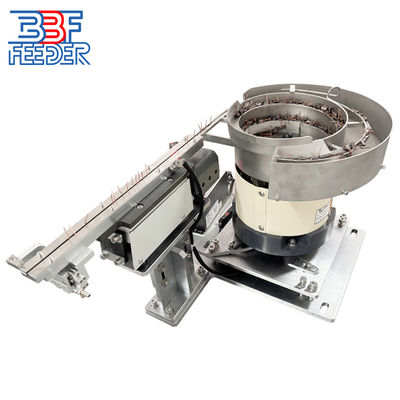

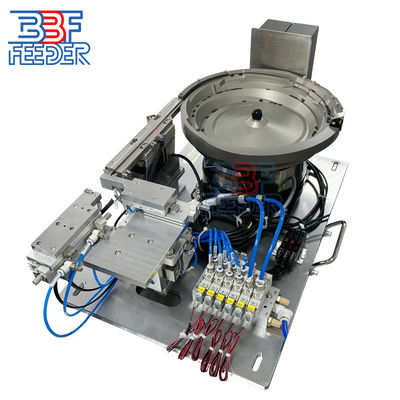

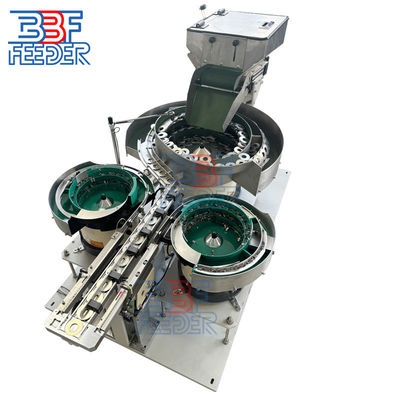

Carbon Brush Vibratory Bowl Feeder High Performance Automatic Customized Parts Feeder

1 . Descriptions:

Vibratory bowl feeders deliver significant value to production lines by reducing labor and time costs. They are often integrated with automated production equipment—such as filling machines and packaging machines—to further enhance overall production efficiency, creating a seamless and high-performance workflow.

As fully customizable material handling solutions, vibratory bowl feeders can be tailored to meet the specific requirements of different production lines. For instance, if a customer requires continuous material supply over extended periods, a hopper can be added to the vibratory bowl feeder. This hopper acts as a material reserve, ensuring a steady and uninterrupted flow of materials to the feeder, which in turn guarantees the continuity of the production process.

If your production line is in need of automated equipment integration, please do not hesitate to contact us. We are committed to providing you with personalized, custom-built solutions that align with your unique operational needs.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

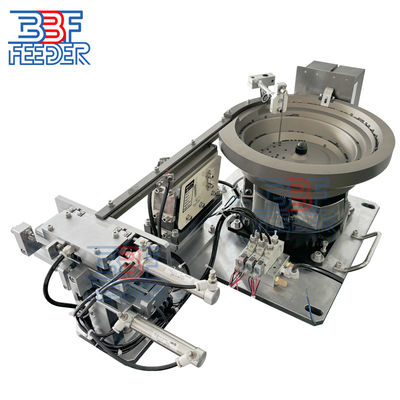

3 . Auxiliary Equipment for Vibratory Bowl Feeder

To adapt vibratory bowl feeders to diverse production environments, engineers integrate tailored auxiliary equipment during design—boosting functionality, safety, and efficiency:

Sensors: Photoelectric sensors monitor material flow for uninterrupted transport; inductive sensors pinpoint metal material positions.

Control System: Acting as the "brain," a PLC coordinates multi-device operation, a frequency converter adjusts vibration frequency, and a touchscreen enables easy parameter setting and real-time status monitoring.

Hopper: Expands material storage and auto-replenishes low levels, cutting manual refilling and ensuring steady material supply.

Protective Cover: Maintains a clean environment (critical for food/pharmaceutical/precision applications), prevents material splashing, and can be fitted with acoustic cotton to reduce operational noise.

4 . More Pictures:

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!